Any gearhead worth his or her salt knows that whether it's a SOHC, DOHC, or OHV engine, the camshaft is considered the brain of a four-cycle internal combustion power plant. The camshaft's profile tells the intake and exhaust valves when to open and close, as well as how much to open. Replacing a pushrod engine's camshaft with a more aggressive aftermarket unit is a serious performance upgrade that can change the entire personality of an engine. For example, emphasizing more torque or more horsepower, and the peak RPM range for those forces to occur.

However, replacing your camshaft is a major undertaking that's outside the realm of many shadetree mechanics. At best, the entire front dress of the engine needs to be removed to gain access, and probably the radiator. In particularly tight quarters, the engine could need to come out of the vehicle in order to access the cam. For a much more budget- and labor-friendly valvetrain upgrade, consider building horsepower by replacing your engine's rocker arms instead.

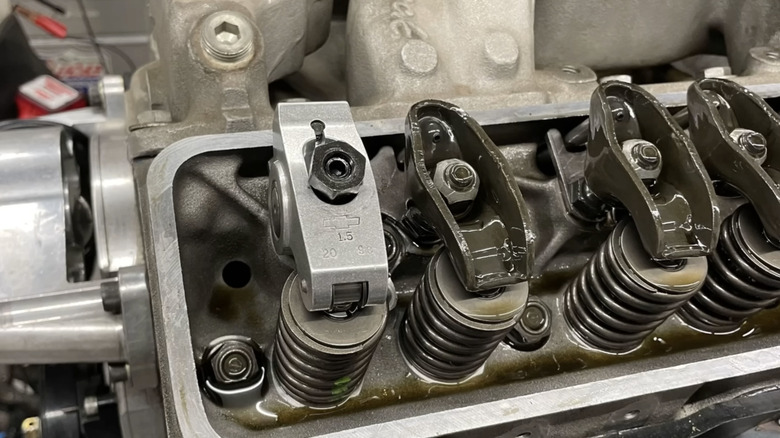

When the camshaft's lobes push on the engine's, ahem, pushrods (via a lifter), the pushrods push up against one end of the rocker arm, forcing the other end of the rocker arm down, which opens the intake or exhaust valves to feed air and fuel into the engine or remove the spent combustion gases. Think of the rocker arm like a lever or a seesaw. The ubiquitous small-block Chevy V8, for example, has 16 rocker arms. That's one for intake and one for exhaust for each of its eight cylinders.

Excepting factory high-performance roller motors, most stock rocker arms are economically constructed from a stamped piece of steel and pivot on a metal ball that's really more like a half circle. As you might imagine, the metal-to-metal contact of these components creates a lot of friction, which robs efficiency and horsepower. To eliminate some of that friction, consider upgrading to rocker arms with a roller tip. They're similar to stock rocker arms, but with a small metal wheel at the tip of the rocker that contacts the valve for smoother action and reduced wear.

To reduce friction even more, hot rodders can opt for a more expensive set of full-blown roller rockers. Typically made from billet aluminum, roller rockers not only have a roller tip, but the entire assembly rotates on bearings instead of a pivot ball. Some experts claim that upgrading to roller rockers can free up more than 20 horsepower on an average domestic V8 engine.

Getting a 20 horsepower bump just by reducing valvetrain friction from the roller rockers might seem too good to be true. Spoiler alert — it is. That's because when rocker arms are replaced — either with roller tip or full-roller units — the rocker arm's ratio is often upgraded at the same time. The rocker arm ratio effectively multiplies the amount of lift from the camshaft and applies it opening the valve.

For instance, a typical small-block Chevy like the much-maligned 305 has a stock rocker arm ratio of 1.5:1. A cam lobe with 0.3 inches of lift multiplied by 1.5 equals a valve lift of 0.45 inches. Now consider an aftermarket roller rocker arm with a 1.6:1 ratio. That equates to 0.3 inches of camshaft lift multiplied by 1.6 equals 0.48 of valve lift, or the amount the valve opens into the combustion chamber.

Basically, utilizing a higher rocker arm ratio is similar to installing a high-performance camshaft with more lift, but without the hassle and expense of actually swapping a cam. In a Motor Trend dyno test, a small-block Ford picked up 10 horsepower and a whopping 16 lb-ft of torque by changing to 1.72:1 ratio rockers compared to the stock Ford ratio of 1.6:1.

If going from 1.5 to 1.6 ratio rockers in your small-block Chevy is good, then a 1.7:1 ratio must be even better, right? Not necessarily. Beware getting carried away with rocker arm ratios in a relatively stock engine. Without special modifications, potential problems include pushrods binding, pistons hitting the valves, and rocker arms hitting the stock valve covers. Although it's beyond the scope of this article to explore the limits for every type of engine, there's loads of information available online as to what combinations work without significant modification.

So how much does a 10 to 20 horsepower bump from new rocker arms cost? Sets of roller tipped or full roller rocker arms for common domestic V8 engines are available from vendors like Summit Racing and Jegs starting in the $200 to $300 range. Although it's easy to spend double that amount or more for certain brand names and trick anodized finishes.

Also note that while not always 100% required, upgraded roller rockers are often paired with new pushrods and possibly new valve springs to fresh up the entire valvetrain and ensure that all components play nicely together. Some assembly is required, as they say, but this job is certainly within the realm of the handy do-it-yourselfer with no special tools required.

Facebook Conversations